Search This Supplers Products:CNC Machining ServiceHot forging PartsMetal Stamping PartsPrecision Casting PartsMetal Welding Parts3D Printing Service

Choosing between 3D printing and CNC machining

publisherAlex.Chai

time2020/07/16

- Choosing between 3D printing and CNC machining

Choosing between 3D printing and CNC machining

When it comes to materials and products for your business, choosing the right manufacturing technique is key to keeping things running smoothly.

2D printing is notably the most well known form of printing, however 3D printing is one of the most versatile production techniques, but it may not be the best for a company’s specific projects. CNC machining is the right strategy if companies need help deciding which manufacturing technique is right for them. Here’s some information to get started.

A 3D printing service prints designs by adding layer after layer of material (additive manufacturing). In a way, a CNC machining service offers the opposite.

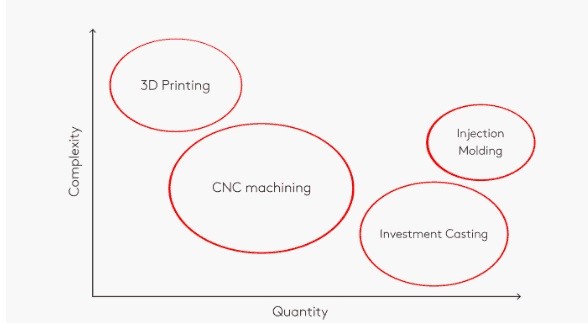

CNC is considered subtractive manufacturing since tools remove material until the desired shape is reached. While both processes work with similar materials, a 3D printing service is often the better option if you need a small number of parts quickly and at the lowest price. A 3D print is also good for more difficult designs and materials. However, CNC is lauded for accuracy, which is great for mechanical parts.

While CNC does have certain limitations regarding the angles of some tools, this process can be used for small and large projects alike. 3D prints have a thickness designated by the printer nozzle, and often the layers are visible in the finished product. 3D prints also often have a smaller maximum size due to the production area.

When it comes to materials, a CNC machining service performs well with metals, whereas 3D prints are typically made of plastic (though a variety of other materials are utilised). If a company wants sturdy, reliable mechanical parts, CNC is a dependable method, but 3D prints don’t have many geometric shape limitations.

CNC is easily the most labor-intensive

Of the two processes, CNC is easily the most labor-intensive. An expert needs to select tools, speeds, and repositioning options, and all of these decisions will impact the final product, including the production time needed. The final piece may still need finishing. On the other hand, a 3D print begins quickly with the design file that is sent to the printer.

Once the print is completed, the product will likely need to be cleaned and possibly polished or otherwise finished.

How can a company decide which process is best?

It’s fairly simple – a CNC quote is ideal for quantities of about 250-500 that don’t require complex shapes, whereas a 3D print is best for more complex shapes, prototypes, and small quantities. If an order exceeds 500 items, it may be better to consider other processes as well.