Search This Supplers Products:CNC Machining ServiceHot forging PartsMetal Stamping PartsPrecision Casting PartsMetal Welding Parts3D Printing Service

CNC Machining or Machining Process to make Molds

CNC Machining or Machining Process to make Molds

In general, machining or machining refers to the art of shaping different types of materials, with the help of a CNC or conventional machine. In this specific case we are talking about a CNC machine, in which it is essential to know different types of strategies, cutting parameters and characteristics of the different materials.

At Art machining they are specialists in providing CNC machining services, so their workforce is highly qualified and all of their operators have vast experience in machining molds and spare parts for them, always ensuring and having careful attention to quality.

The machining process may seem simple, but it really has a high degree of complexity, since it is the first process and requires a high level of precision, taking into account tolerances and always paying greater attention to details that may affect the operation of the mold. ; It is also ideal to talk about machine finishes, as this part can help a tool maker to make a good adjustment of the mold seal.

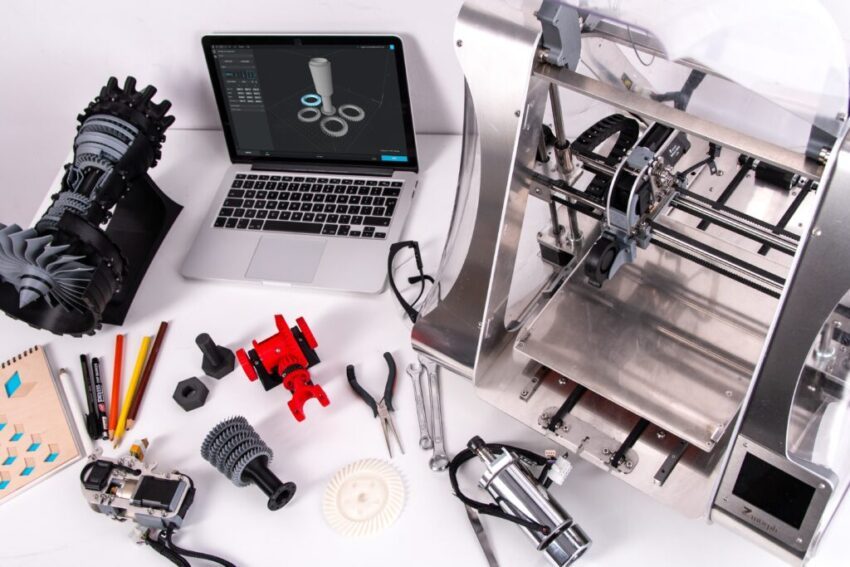

CNC is the material cutting procedure with a computerized numerical control machine. The main advantage of this process is that CNC produces parts that can replace the prototypes manufactured with additives for production-quality materials. The method allows printing parts on the material to be used for production. CNC machining is the ideal choice for high-quality metal and plastic parts for high-precision machining that requires maximum precision, surface finish and material properties.

Prototype Parts or Fast Manufacture – We have the CNC machining options suitable for the production of plastic or metal parts.

- Wide range of materials

- Comply with the highest tolerance

- Parts processing directly from CAD 3D models

- Standard delivery time of one to two weeks, depending on order

- Delivery times may be shorter, depending on available capacity