Search This Supplers Products:CNC Machining ServiceHot forging PartsMetal Stamping PartsPrecision Casting PartsMetal Welding Parts3D Printing Service

Aluminum Alloys

All About Aluminum Alloys

Aluminum alloys are used in a variety of ways, they are used to make common everyday items like kitchenware and utensils, to being used in the auto industry to make lighter weight vehicles, to aluminum siding on homes, to use in aerospace, where they are strong enough to withstand the rigorous temperature changes while maintaining their shape.

What are Aluminum alloys?

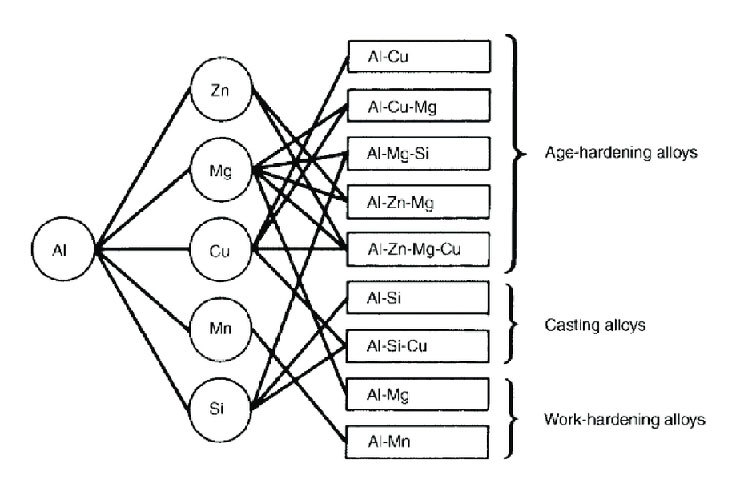

An alloy is a metal mixed with either other metals or non-metallic elements. Aluminum alloys are materials largely consisting of aluminum, but with other elements such as iron, copper and magnesium mixed in.

Depending on their composition, different aluminum alloys are suitable for different applications. The mixture of other elements affects an alloy’s physical properties, including its strength, ductility and corrosion resistance, and these properties can help a company decide whether the material is suitable for a given part.

Aluminum grades can be broken down into three groups: commercially pure aluminum, heat-treatable alloys and non-heat-treatable alloys. Since commercially pure aluminum is less regularly used in CNC machining (we can, however, machine parts using Aluminum 1060), this article focuses on five alloys from the latter two groups.

The Use Of Aluminum Alloys

Aluminum alloys are used in a variety of ways, they are used to make common everyday items like kitchenware and utensils, to being used in the auto industry to make lighter weight vehicles, to aluminum siding on homes, to use in aerospace, where they are strong enough to withstand the rigorous temperature changes while maintaining their shape. The weak aluminum used to make the soft drink cans can do that much when turned into an alloy compound.

More About Heat Treatment of Aluminum Alloys.

In cold temperature aluminum alloys, the tensile strength of aluminum typically doubles but the heat treatment of aluminum alloys produces a much stronger, much more controlled strength and weight to an alloy that can be rendered when a cold temperature is employed to do the same task. High temperature aluminum alloys are employed to temper the aluminum and allow the alloy to reach a specific mechanical strength. This is typical of aluminum alloys used in the aircraft, shipping, or auto industries. Each of these used the cost effective, lightweight aluminum in many different alloys, depending on the parts that are being crafted from it.

Features Of Aluminum Alloy

There are hundreds of different aluminum alloys being employed in industries across the world today. It’s the features of aluminum alloy that makes it a staple to almost any commercial and industrial application. Below are some of the notable features of aluminum alloy:

Widely used in numerous applications from small toys to aircrafts

Recyclable and reusable which makes it a valuable resource in an economy

Slow to corrode, making it very sought after in the transportation business

Incredible lightweight makes it an ideal pairing to heavier metals

Better elastic modulus properties compared to steel making it easier to deform to the desired shape or orientation

Lower melting point compared to other metals making it a suitable material for small scale usage without needing extremely high temperatures

Common Aluminum Alloys We Process

Heat-treatable alloys

Aluminum 2024

Aluminum 2024, one of the more widely used of the ‘duralumin’ aluminum alloys in the 2xxx group, is a copper-alloyed material with an excellent strength-to-weight ratio. It is resistant to fatigue but fairly susceptible to corrosion.

Tensile strength: 68,000 psi

Major alloying elements: Copper

Industries: Automotive, aerospace, transportation

Products: Car parts, aircraft parts, transport vehicle parts, structural parts, electronics

Aluminum 6061

Aluminum 6061 is the most widely used alloy in the 6xxx series and one of the most versatile of all machinable alloys. By CNC machining aluminum 6061, it is possible to make a wide range of products, including electronic and aircraft parts.

Tensile strength: 45,000 psi

Major alloying elements: Magnesium, Silicon

Industries: General manufacturing, aerospace, consumer goods, architecture

Products: Structural parts, steps, platforms, covers, truck bodies, valves, pipes, aircraft parts, computer parts, electronics

Aluminum 7075

Commonly used for highly stressed structural applications, Aluminum 7075 is often found in structural aircraft parts, as well as sports equipment, tooling and more. 7075 is heat-treatable, ductile, strong and tough, but can also become brittle.

Tensile strength: 83,000 psi

Major alloying elements: Zinc

Industries: Aerospace, transportation, sporting goods

Products: Aircraft parts, transport vehicle parts, bicycles, golf clubs, weapons

Non-heat-treatable alloys

Aluminum 3003

The most widely used aluminum alloy (across all manufacturing processes), Aluminum 3003 is a near-pure aluminum alloyed with Manganese. It is frequently used for household goods like cooking equipment.

Tensile strength: 13,000 psi

Major alloying elements: Manganese

Industries: Household goods, chemicals

Products: Cooking utensils, kitchen equipment, tanks, siding and trim, roofing, chemical equipment

Aluminum 5052

Strong, workable and corrosion-resistant, Aluminum 5052 — made with magnesium and chromium, amongst other components — is widely used in marine applications because of its resistance to salt water. It is also the strongest non-heat-treatable alloy available.

Tensile strength: 33,000 psi

Major alloying elements: Magnesium, chromium

Industries: Marine, aerospace, architecture, electrical, oil and gas

Products: Marine transport parts, heat exchangers, aircraft parts, fuel lines, fuel tanks, panels, household appliances, commercial and heavy-duty cooking equipment

How to Choosing a Suitable Aluminum Alloy for Your Parts

In addition to the sample of materials mentioned here, Zehan Machinery MFG offers CNC machining and die casting services in several other alloys. When getting a rapid quote from us, you can select one of these alloys drop the drop-down list of materials, or choose one of many non-aluminum materials instead.

If you’re not sure about what kind of aluminum alloy suits your parts or prototypes — or if you think your part should be machined from an alloy not on our list — you can request a manual quote and specify the requirements of the project.

With this information, we can help you decide on the best material for the job, ensuring that your parts get made exactly as you want them.